ripplex - Formed Components from Corrugated Cardboard

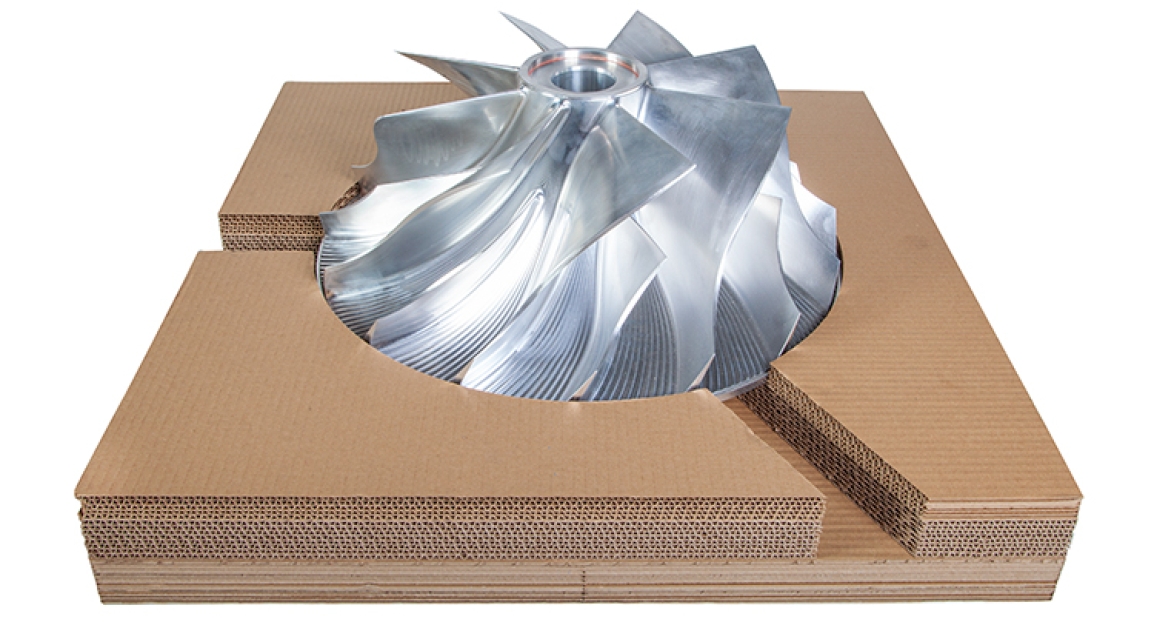

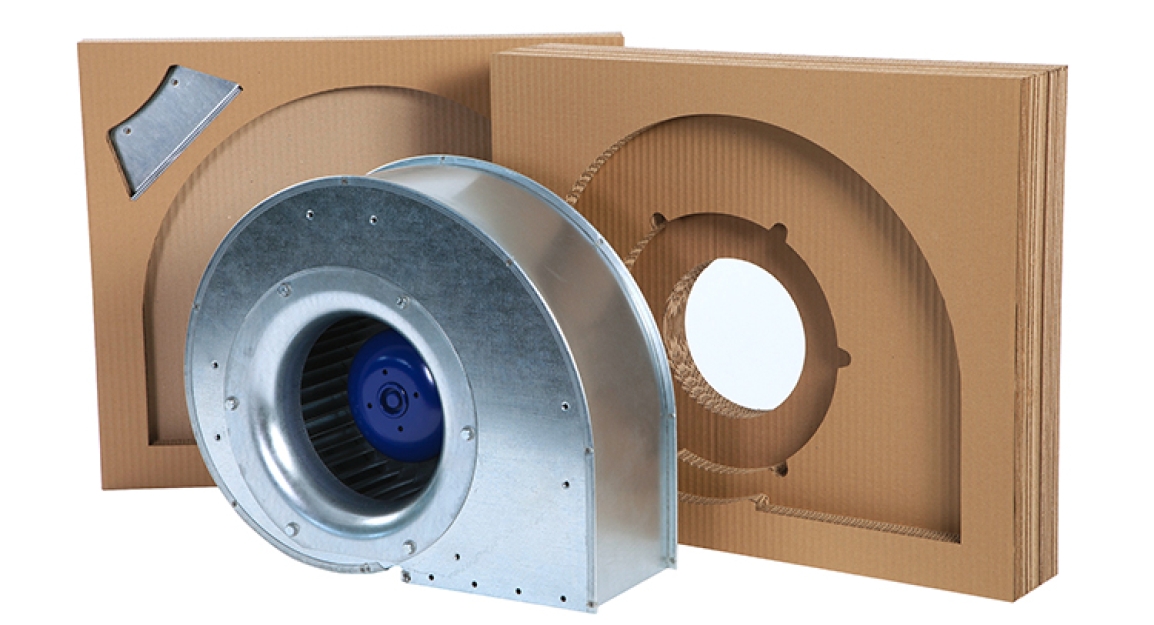

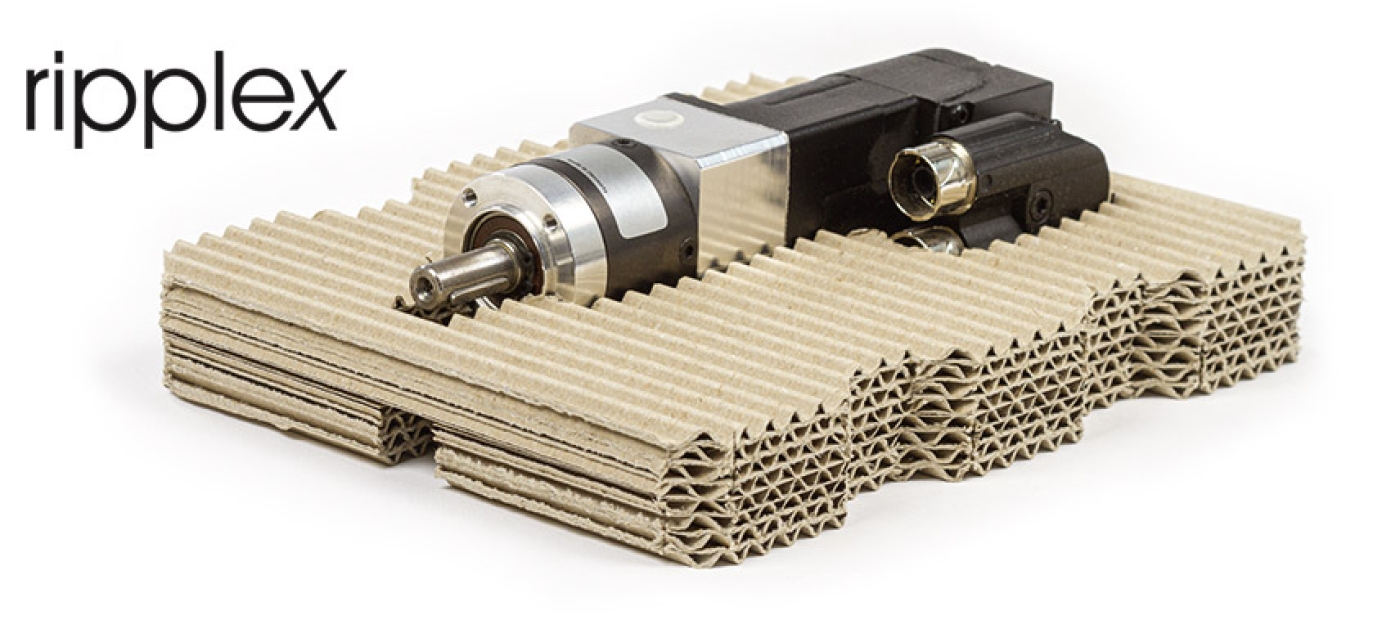

ripplex parts are ecological formed components made of laminated corrugated cardboard sheets. Here we offer you a packaging material that saves time in the process of packing and eliminates the need for other materials. They provide high protection during transport, as they are load-bearing and resilient. Individually executable on request, with complex and accurate shapes and nests.

The sustainable and adaptable ripplex inner packaging solutions made of corrugated cardboard can be used almost everywhere.

ripplex is created by laminating several layers of corrugated cardboard on top of each other before processing. Due to this technology and thanks to the special corrugated board properties, with ripplex we have a damping and highly stable packaging solution in our portfolio for the packaging industry. After all, fragile products require reliable protection during transport. The automatic and accurate sheet processing of different corrugated board grades and shapes characterize the final product. Interior cutouts or nesting are also possible without any problems.

The production of the packaging is therefore characterized by high contour accuracy. In addition, variable incisions can be made for retaining bars. Depending on customer requirements, perforations and incisions in all directions are possible as well. By using different cardboard grades, thicknesses and corrugation heights, the cushioning effect can be precisely determined at the end. In this way, we form high quality and very efficient inner packaging from paper that has been recycled several times.

Examples: Corner pads, wrapping pads, U- or L-profile pads or simple sheet pads, from soft to hard.

Contact DE-PACK now if you need an appropriate ripplex solution for your products.