A computer-based and almost completely automated warehouse for small parts is referred to as an "Automated Small Parts Warehouse" (AKL). The storage and retrieval of items carried out there is done systematically with the aid of so-called " mini-load bins", which make a significant contribution to ensuring that the IT-guided work process is carried out efficiently and safely. As a result, the small parts can be retrieved centrally at the predefined destination.

DE-LINE – Exceptionally Dynamic and Versatile

Our space-saving mini-load containers DE-LINE can be computer controlled and fully automated with short access times on conveyor or roller belts by means of stacker cranes or shuttle vehicles. The AKL plastic containers are reinforced in order to meet the special requirements and storage needs; for example, with a special flange floor, which is significantly more stable than a normal container floor. Furthermore, there is a ribbed rim that provides a better stability on the conveyors. The robust plastic material of a modern mini-load container guarantees a long service life.

The sorting options and the filling volume of an AS/RS container are constrained in some cases. Therefore, compartments or inserted separators (e.g. HKP compartments) in many mini-load containers ensure safe transport of small parts (e.g. screws or electronic parts). A wide variety of small parts can be efficiently stored in one container and dynamically removed as needed.

Advantages

- Fully automatic operation by stacker cranes or shuttle vehicles

- Picked items reach the order processor quickly via software-supported stacker cranes

- After unloading, the automatic systems transport the mini-load container back to its storage location

- Processes run fully automatically via the control software to generate the corresponding retrieval for specified orders

- No travel times, just short access times

- High transfer rate, with a large variety of items

- Single or multiple position storage of a mini-load container in the rack bay

AKL Euro containers of the type DE-LINE are primarily used in conveyor technology as well as for automated processing.

Highly Dynamic and Efficient Processing with AKL Containers

DE-PACK storage and transport containers are indispensable for stacking, storing, order picking and forwarding, as they greatly facilitate warehousing. From technology articles such as computer chips or electronic components to screws and a wide variety of plastic parts, our DE-LINE mini-load containers are ideal for any application, as they support fully automatic processing in automatic small parts warehouses.

Design

With a reinforced base design and a circumferential stacking groove, our DE-LINE container product line can shine. Due to cleverly designed struts, the plastic Euroboxes can carry a multiple of the filling weight at a low dead weight and thus ensure absolute functional safety. For example, the stacking of several containers is possible without any problems. Ergonomic handles ensure optimum handling and thus promote comfortable and safe working. Adhesive surfaces for barcodes on the side walls are another feature of the containers.

Properties

Plastic containers are pure logistic containers perfectly qualified for use in automated conveyor systems, as well as automated handling. Our container system DE-LINE is modularly adapted to the base areas 1200 x 800 mm and 1200 x 1000 mm. This means that it can be easily combined with other standardized products from the storage and transport sector.

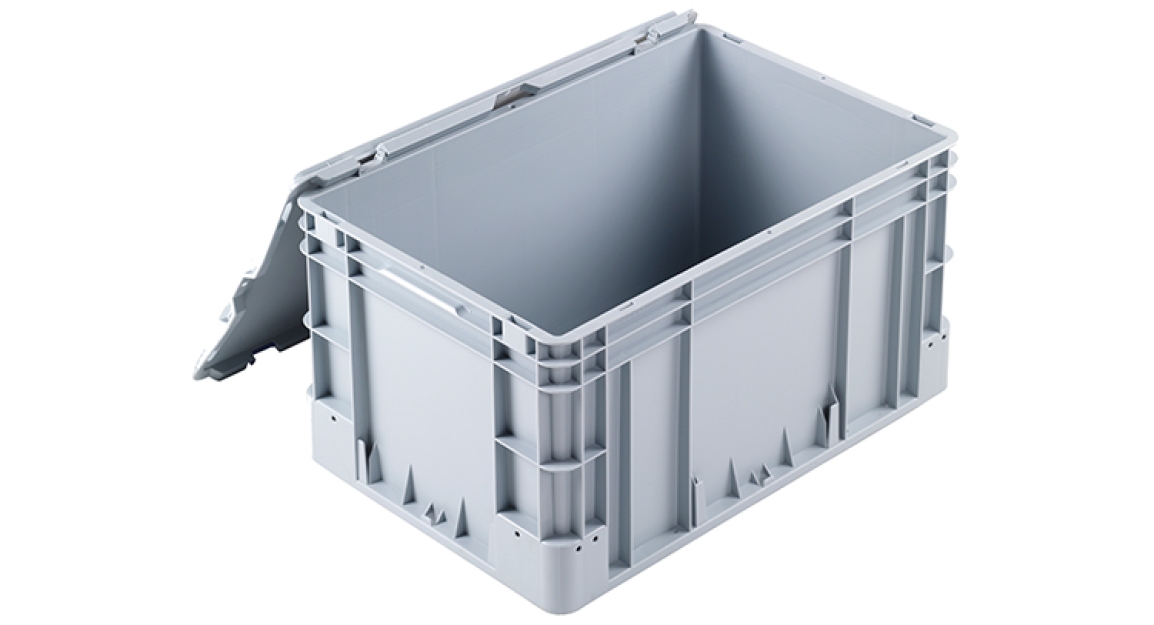

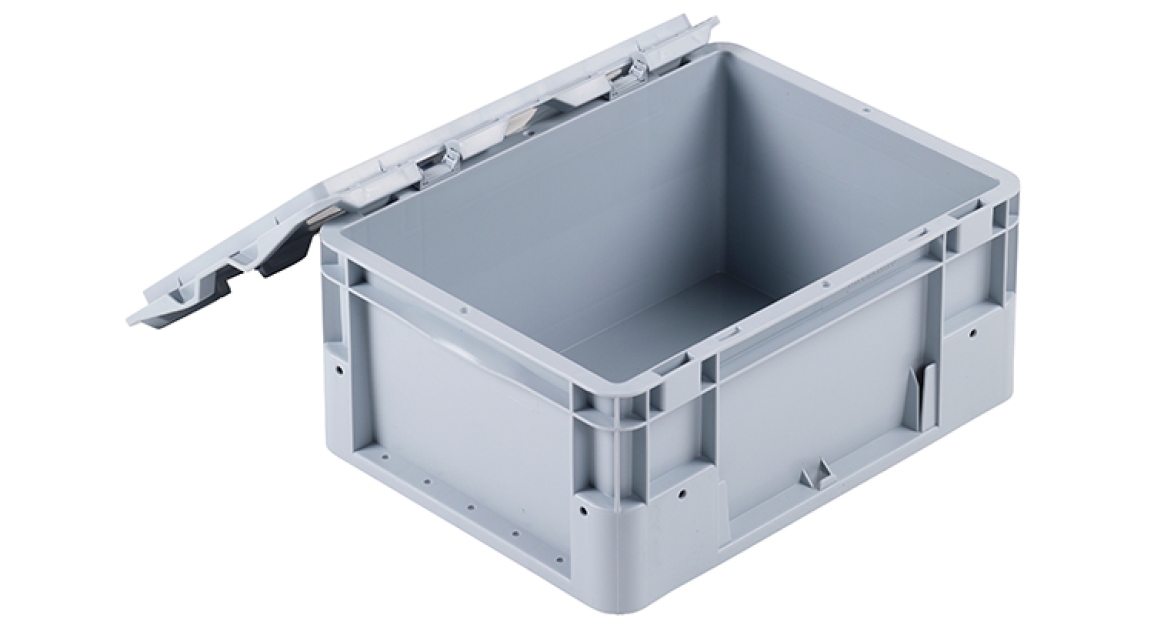

AKL Container with Lid

The DE-LINE plastic containers with lids are ideally suited for the industrial application areas of conveyor technology, as well as for automated handling. On request, we can supply the corresponding hinged and support lids to match the entire range of containers. Choose from a wide range of variants, with openwork handles, with smooth walls or with label holders. All DE-BASIC plastic boxes are dimensionally matched to Euro pallets, industrial pallets or roller containers and can be stacked on top of each other without any problems.

Lid versions

The low-stiffening DE-LINE support lids or hinged lids (mounted) made of polypropylene (PP) are compatible with the gray/silver-colored DE-LINE Euro container series and are available with the appropriate dimensions.

The lids seal the plastic container dust-tight. Your goods are thus ideally protected from transport damage, but also from soiling. A great advantage is that the plastic containers can still be stacked even with an attached support/hinge lid.