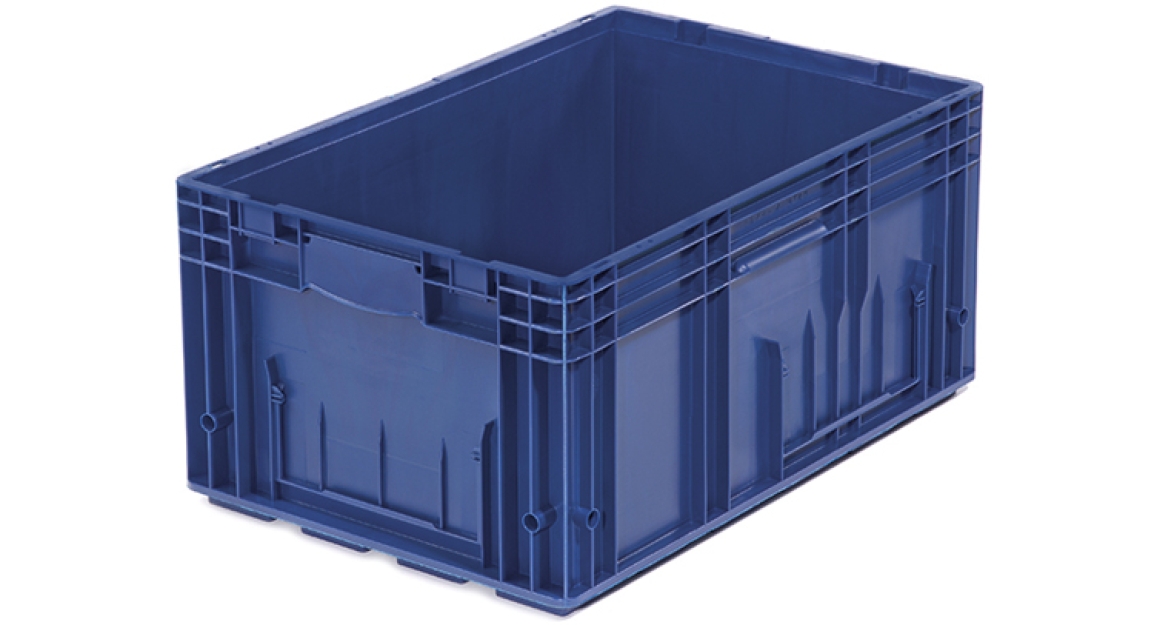

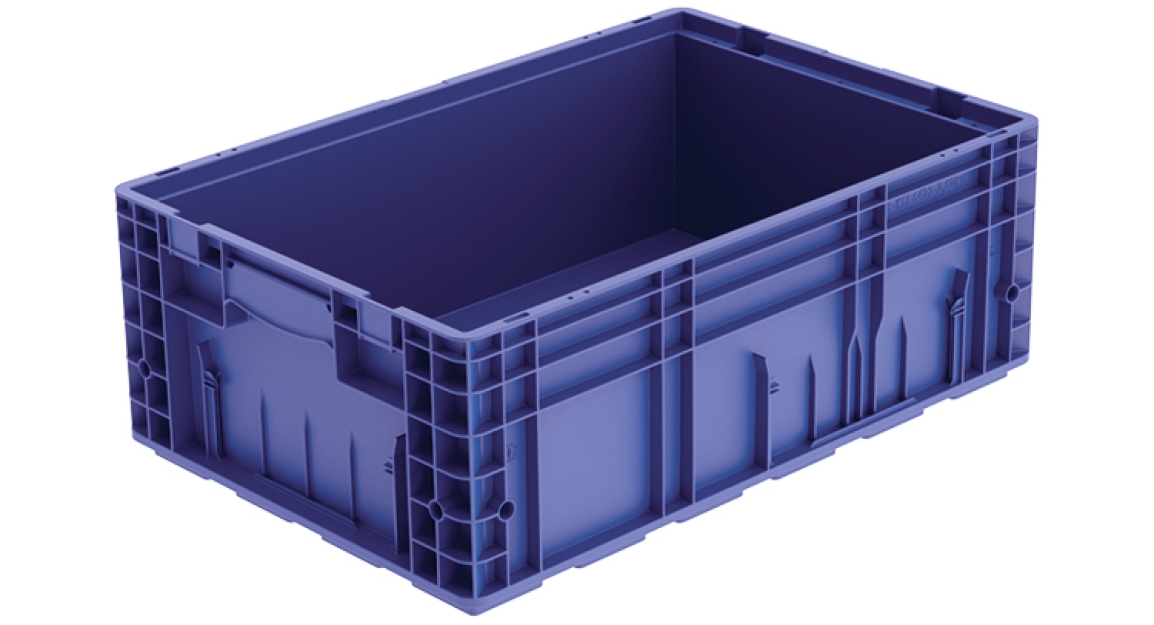

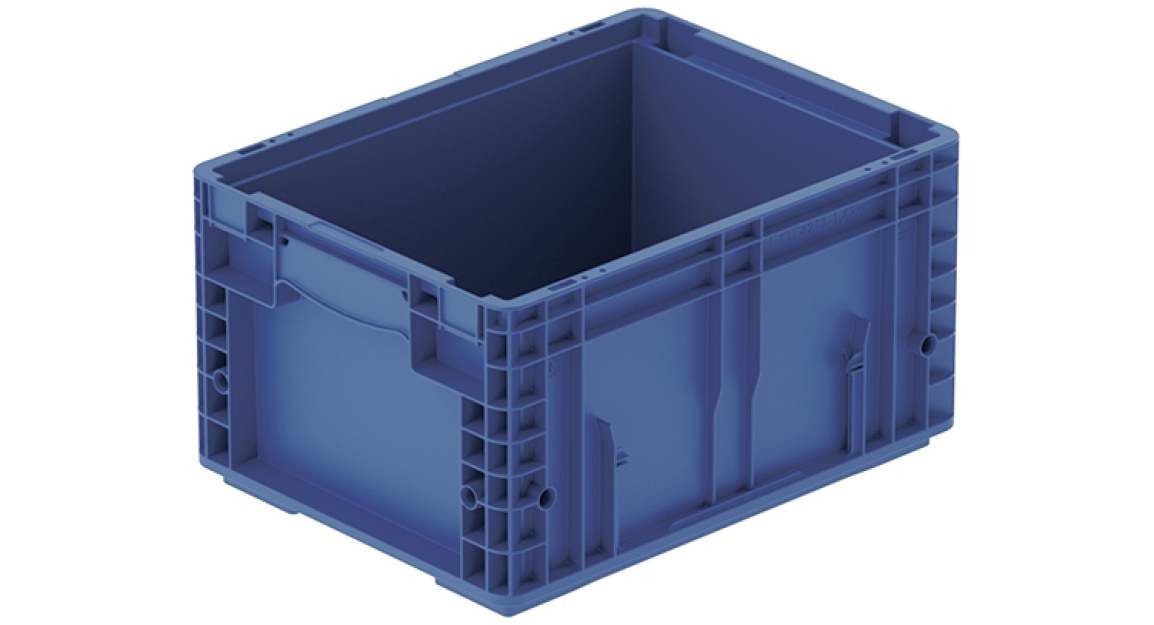

VDA-R-KLT

VDA 4500/4504 (German Association of the Automotive Industry) compliant KLTs have become an indispensable part of today's highly automated production processes. The main feature of the robust small load carriers is a rigid composite base. The material consists of 100% polypropylene, the temperature application range is -20 to 100 °C and the containers are also largely resistant to oils, alkalis or acids.

Small load carriers, often referred to as "KLT", are standardized load carriers that are made of polypropylene and can withstand even extreme temperatures due to their robust nature.

The useful volume of the small load carriers is optimized for industrial processes and compatible with other Euro-size containers and KLT variants. The standardized containers save space, can be used several times, are ideally suited for stacking on pallets and are also fully recyclable. Especially in the automotive sector, where reusable packaging for small parts or sensitive products is in demand, small load carriers provide optimal use.

Design

The VDA-R-KLT container product line is equipped with a stable ribbed base including stacking feet and a circumferential stacking groove. Thus, the blue containers made of polypropylene (PP) ensure absolute functional safety even when filled. The stacking of several containers is possible without any problems.

Ergonomic handles on the sides provide optimum handling and ensure comfortable and safe use. Another feature of the load carrier are adhesive areas for barcodes on the side walls.

Advantages and Features

Predominantly used in the automotive industry, KLT small load carriers are perfectly suited for use in highly automated manufacturing processes and are universally applicable. VDA-R-KLT container are modularly adapted to the base areas 1200 x 800 cm and 1200 x 1000 cm. This means that our KLTs can also be combined with other standardized products from the storage and logistics sector without any problems. High loads are no problem thanks to additionally reinforced abutment surfaces on the front and long sides of the containers.